- Design 360 woodworking software#

- Design 360 woodworking professional#

- Design 360 woodworking series#

Design 360 woodworking professional#

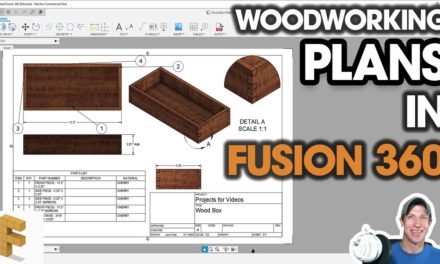

However, I think if I would have professional woodworking service I would go to Autodesk Fusion 360 with JoinerCAD extension, becuase for me this looks good.īut my world looks a little different.

Design 360 woodworking software#

The process can be simulated to check and then posted out to GCODE.A good source of inspiration would be the concepts presented in the JoinerCAD presentation videos:Īutodesk Fusion 360 with JoinerCAD extension is like another time dimension not accessible for FreeCAD right nowĪutodesk is huge software designed for such things for many years and it costs really a lot, personally I can't afford it. Once the relevant geometry for each operation is selected the toolpaths are generated.

Design 360 woodworking series#

Setting up a series CAM operations can be done once with all operations it the feeds/speeds and tools you use typically and then saved as a template for furniture the following operations are typical (in a similar order):Īn example of a template for operations can be downloaded To set the Work cordinate system the easiest way I have found is to set the “Orientation” field to “Select Z axis/plane & X axis” then select the top face of a component. It is really important to set the WORK CO-ORDINATE SYSTEM correctly! (Note: this is independent of the MODEL CO-ORDINATE SYSTEM) Be consistent – I always use the bottom of the stock as Z=0. Switch to cam mode! Setup the job by selecting all the components. From here we can define points near to each component where a drill hole can be made to screw the sheet down to the spoil board. In the sketch use the “project” tool to project all of the body geometry onto the sketch. We can now create ANOTHER sketch (call it: “LAYOUT”). The plugin is available from: The dogbones overcut internal corners allowing components to fit together Next, we want to apply dogbones to the layed out components. The layout below has been manually adjusted to optimise for space. You can also define the stock size so components are laid out within the perimeter of the material.

I recommend the tool which automatically copies bodies from the model and lays them out based on the smallest dimension (thickness).

Now we can lay out the components for machining. We select the male component as the tool component and the female component as the target body. We can then use the combine tool to do a boolean operation. We will start by PRESSING the fingers into one of the components which is to become the male component. To do this We should use the user parameter MAT_THICKNESS to define the length that the fingers extend into the component. Next we can create some mirror planes through the axis of symmetry from which we can duplicate components to fill out the structure.įollowing this, we create the joints of our components. In this example there is a high degree of symmetry, so one side panel, one leg and one shelf only are modelled it this stage. Only create one component for each unique component at this stage (that way repetitious work can be avoided later). Next, create local sketches on the planes of principle components. This should contain the detail of where principle components are to be aligned. You should try to get most of the details that will drive the design in one sketch.

Sketch (on paper) – the idea needs to be nearly fully formed before trying to model it, otherwise you will end up with a hot mess. Doing this ultimately reduces design time and creates a model with a robust structure and timeline that allows modification in the future should it be required. The key strategy of the workflow is to work from a high level creating a framework and to work down adding detail as the design is developed. Key to success, is following a clear process that allows for modification as the design develops A winning workflow Although the example is specific to cabinetry, the principles can be applied for any kind of modelling. The following is a recommended process for design development in fusion 360.

0 kommentar(er)

0 kommentar(er)